It represents the loss of inventory due to factors like theft, damage, or administrative errors. Regular meetings with suppliers alleviate concerns, address issues, and strengthen relationships, contributing to a more reliable supply chain. Most inventory-driven businesses do an annual inventory count, called an audit, for tax purposes. This compares a physical count of all goods in stock to the inventory quantity on hand (QOH) shown in the data records.

A Comprehensive Guide to Inventory: Navigating the Complexities

Health and Safety Officer duties entail the identification and prevention of potential workplace accidents and health hazards. It is the safety officer’s responsibility to ensure company compliance with exist… In today’s digital era, employee training tracking software sets a high standard for monitoring staff development programmes and safeguarding employee certification records. Claim your free copy today for insights and strategies to protect and secure your digital assets. Tracking inventory in your business or organization with spreadsheets can be tricky. In this article we explore what Inventory Management Software is and 5 reasons why it’s your business’s new superhero.

What Is the Difference Between Supply Chain Management and Inventory Management?

A company’s success and ability to compete in today’s fast-paced market depend on how well its supply chain is handled. Using these methods will help businesses do well and grow, even when things go wrong. In the realm of global supply chain management, adhering to ethical practices is paramount. Ethical issues relating to labor practices, environmental impact, and corporate governance https://www.bookstime.com/ cannot be overlooked. By embracing a comprehensive approach to SCM, companies can not only navigate disruptions more effectively but also turn potential challenges into opportunities for growth and innovation. In this context, the role of a supply chain manager transcends traditional boundaries, making them key strategists in the quest for sustainable competitive advantage.

Prioritizing Best-Selling Items

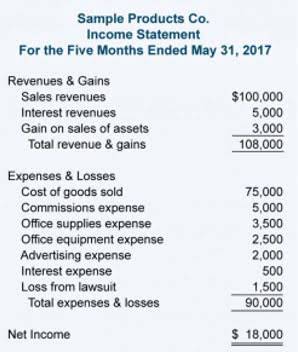

For instance, a furniture manufacturer would consider wood, nails, and varnish as raw materials. Efficient management of raw materials ensures that production processes are not interrupted due to shortages, while also avoiding excess that could lead to wastage or obsolescence. In today’s fast-paced business environment, managing inventory effectively can be a complex challenge. Businesses need to balance having enough stock to meet demand without overstocking, which ties up capital and increases storage costs. Discover key strategies and technologies for optimizing inventory management in modern businesses to enhance efficiency and profitability. From inventory turnover and carrying costs to fill rate and order accuracy, this section delves into the key KPIs that executives should monitor to optimize inventory management.

- If you stock all products in your own facility, your inventory controls and processes are handled internally.

- Warehouse design not only maximizes space utilization but also affects company profitability by optimizing product flow.

- This will help you plan ahead and make sure that you always have the items your customers want in stock.

- In summary, effective inventory management ensures product availability, promotes customer satisfaction, reduces waste, and fosters sustainability within supply chain organizations.

What Are the Four Main Types of SCM Inventory Management Systems?

(PDF) The Effects of Inventory Management Practices on Educational Service Delivery: A Case Study of Sunyani … – ResearchGate

(PDF) The Effects of Inventory Management Practices on Educational Service Delivery: A Case Study of Sunyani ….

Posted: Thu, 14 Jul 2022 07:00:00 GMT [source]

They should also commit to ongoing staff training and competency development, ensuring their teams are equipped to leverage new tools. Metadata is essential in data inventory management as it assists in understanding, interpreting, and managing data assets effectively. This section delves into the causes of inventory inaccuracies and shrinkage, such as poor tracking systems and inadequate security measures. Ultimately, a reduced order cycle time enables organizations to improve customer service, increase operational efficiency, and gain a competitive advantage in the marketplace.

Elevate Your Inventory Management with Cadre Technologies’ WMS Software

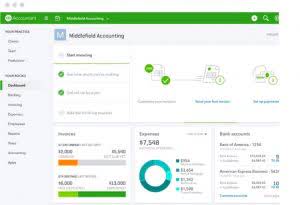

By accessing vendors from various places or with diverse routes and ports, your business can decrease the risk of disruptions due to regional or global events. Supplier diversity enhances your flexibility, ensuring a consistent flow of goods and reducing dependency on a single supplier. With the right inventory optimization strategies for your warehouse, you’ll be able to run a more successful supply chain that leaves you having an adequate stock and well-managed warehouse. This, in turn, will help you boost your efficiency, reduce errors and lower your expenses. This particular strategy entails the use of computer software and other applications in effectively managing inventory.

Inventory Management

A well-managed data inventory boosts data accessibility by providing an organized, searchable catalog of data assets, ensuring stakeholders can readily find and utilize the data they need. Informed by accurate, comprehensive data, decision-makers can derive valuable insights, identify trends, and predict outcomes. On the other hand, a low fill rate suggests potential issues such as inventory shortages, poor demand planning, or order fulfillment inefficiencies.

- Inaccurate inventory records, discrepancies between physical and recorded stock, and theft contribute to inventory shrinkage.

- Inventory management systems can be set up to automatically reorder products from suppliers when you’re down to your minimum quantity.

- This can help enhance the customer experience and build stronger customer relationships.

- It encompasses various stages, including order processing, picking and packing, transportation, and final delivery to the customer.

- Using ERP software designed for inventory management is crucial for efficient stock control.

- These activities enhance visibility and build goodwill among local residents, reinforcing your firm’s positive image.

- Consistent and clear messaging through virtual town halls and press releases helps keep stakeholders informed and engaged, thereby fostering trust.

Using a barcode warehouse management system initially sounds like a small, possibly incidental detail. On closer inspection, a barcode system with the right software creates important conditions for making work… A smart maintenance tracker is primarily used to document the maintenance measures carried out on machines and plants in companies.

- Cycle counting is another valuable technique that involves regularly counting a subset of inventory rather than performing a full physical inventory count.

- Today’s sophisticated fraudsters quickly learn to circumvent this rules-based approach, Pezely says.

- If you have a supplier that’s habitually late with deliveries, frequently shorts an order or is the source of supply chain delays, it’s time to take action.

- It’s no secret that managing inventory successfully can be time consuming and difficult.

- For example, a retail store might count different sections of its inventory on a rotating basis, ensuring that all items are checked periodically.

Below are some of the most common questions we receive about inventory management strategies. Advanced analytics tools can provide you with real-time data analysis of your inventory so that you can make better decisions and improve efficiency. Use advanced online store inventory technology such as RFID tags or barcode scanners to easily track and monitor your inventory levels. This allows you to quickly identify any discrepancies as well as take advantage of any special offers or promotions on certain items in your inventory.